Instrument Specs

We have various instruments for outdoor exposure testing and accelerated weathering testing that reproduce the effect of sunlight, temperature, humidity and rainfall and accelerate the deterioration process to predict the lifetime of each product and material in a relatively short amount of time.

| Type of Tests | Instruments | Manufacturer /Type |

SPEC | Capacity | Main Testing | ||

|---|---|---|---|---|---|---|---|

| Weathering Testing | Outdoor Exposure Testing | Standard Exposure Rack |

— | Open Rack (Angle 30°) |

76samples (100mm×300mm) |

Outdoor Exposure Testing. | |

| — | Thermal Insulation Rack (Angle 30°) |

76samples (100mm×300mm) |

Thermal Insulation Outdoor Exposure Testing. | ||||

| Vertical Exposure Rack |

— | (Angle 90°) | 76samples (100mm×300mm) |

Vertical Outdoor Exposure Testing. | |||

| Horizontal Exposure Rack |

— | Open Rack (Angle 0°) |

76samples (100mm×300mm) |

Horizontal Outdoor Exposure Testing. | |||

| — | Thermal Insulation Rack (Angle 0°) |

76samples (100mm×300mm) |

Thermal Insulation Outdoor Exposure Testing. | ||||

| Raindrop Exposure Rack |

— | (Angle 90°) | 18samples (100mm×300mm) |

Raindrop Outdoor Exposure Testing. | |||

| Under Glass Exposure Rack |

— | Normal Glass (Angle30°) |

39samples (100mm×300mm) |

Light Resistance Testing for Interior Components. | |||

| — | UV Glass (Angle30°) |

39samples (100mm×300mm) |

Light Resistance Testing for Interior Components. | ||||

| Accelerated Weathering (Light) Testing | Fade Meter (2 instruments) |

SUGA/U48H | BP Temperature:63~95℃ Humidity Condition:Under 50%RH | 108samples (65mm×55mm) |

Light Resistance of Resin and Interior Components | ||

| Sunshine Weather Meter (2 instruments) |

SUGA/ WEL-SUN-HC |

BP Temperature:55~85℃ | 70samples (70mm×150mm) |

Accerarated Weathering Testing | |||

| Xenon Weather Meter (3 instruments) |

SUGA/ SX75 |

BP Temperature:63~83℃ Illumination:60~180W/m2(300~400mm) Surface Spray:Use Pure Water Back Spray:Configurable Temperature | 54samples (70mm×150mm) |

Accerarated Weathering(Light) Testing of Interior and Exterior Components, and Coating | |||

| Xenon Weather Meter (1 instrument) |

ATLAS/ Ci4000 | BP Temperature:63~83℃ Illumination:60~180W/m2(300~400mm) Surface Spray:Use Pure Water Back Spray:Configurable Temperature | 65samples (30mm×35mm) |

Accerarated Weathering(Light) Testing of Interior and Exterior Components, and Coating | |||

| CASS Tester | ITABASHIRIKA KOGYO /SQ1000CA | W1300×H500×D600mm CASS Test:50℃ 95%RH Salt Water Spray:35℃ 95%RH | 60samples (70mm×150mm) |

Corrosive Yesting of Metal Panels and Coated Panels | |||

| CCT (Combined Cyclic Corrosion Test) |

SUGA/ CCT-1 |

Salt Water Sspray:35~50℃ Immersion Test:10~60℃ Drying Test:10~70℃ Humidity Test:50~70℃(Humidity:60~95%) | 50samples (70mm×150mm) |

Accerarated Corrosive Testing | |||

| Evaluations | Glossmeter | SUGA/ GS-3K |

SPEC:Standard Value ±1.5 | — | Measure Gloss of Panels and Coated Panels | ||

| Color Difference Meter |

MURAKAMI COLOR/ CMS-35SP | SPEC:Standard Value ±1.5 | — | Measure Color Differences of Panels and Coated Panels | |||

| Color Fastness Tester |

DAIEI KAGAKU SEIKI/ LA0-40 | — | — | Measure Fastness of Fabrics | |||

| Pencil Hardness Tester |

TOYOSEIKI | — | — | Measure Surface Hardness of Coating Films etc. | |||

| Adhesiion Test | X-cut | — | — | — | Coating Adhesion | ||

| Cross-cut (Grid) | — | — | — | Coating Adhesion | |||

| Digital Camera | — | — | — | Digital Photography | |||

| Digital Micro Video Scope |

KEYENCE/ VH-8000C | Lens:x0~40、×35~245、×150~800、×25~175、×500、×1000 Performance:211Mpixcel、Digital Compositing Fiberscope, Digital Color Printer | — | Analyze Stains and Micro Cracks etc, Observe Inside of Structures(Fiberscope), Conformation(Digital Compositing) |

|||

Characteristic Data

The characteristics of the environment in Kagoshima cause deterioration to materials and are utilized in exposure testing. This is shown in the following data.

The number of explosions from Sakurajima

Acid rain

Acid fog

Volcanic ash

Ion concentration in rainwater

Components in rainwater

Sea salt aerosol

Sea salt aerosol

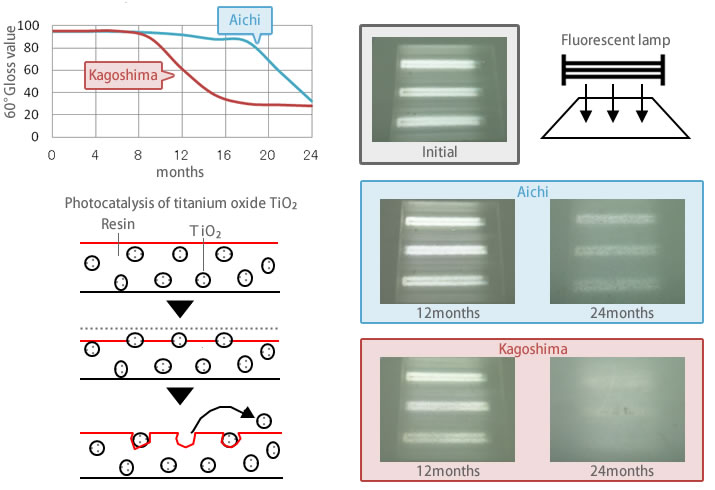

①Decrease in gloss value of Shell Coating

Decrease in gloss value of Shell CoatingDeteriorative acceleration of materials

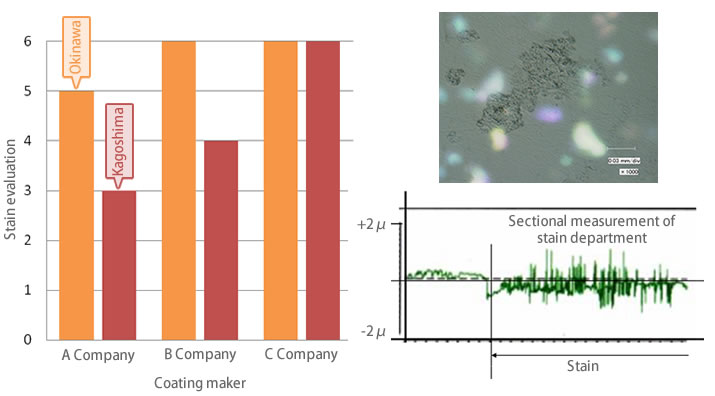

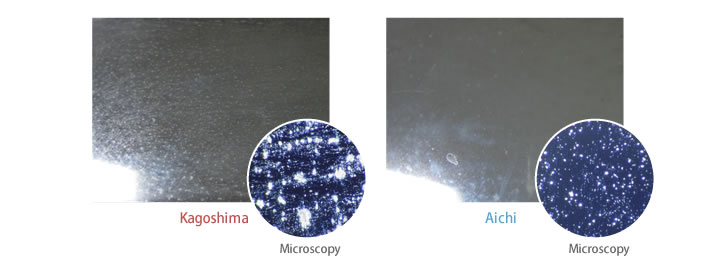

②Evaluation of Shell Coating Stain(5 months)

Evaluation of Shell Coating Stain(5 months)③Evaluation of Pit of Plating

Evaluation of Pit of Plating| ~50μm | 51~100 | 101~200 | 201~300 | 301~ | |

|---|---|---|---|---|---|

| Kagoshima | A large number |

76 | 38 | 13 | 3 |

| Aichi | A large number |

45 | 1 | 0 | 0 |

Weather Data

We take weather data at each exposure site.

| Item | Unit | Kirishima Exposure Site |

Sakurajima Exposure Site |

Kushikino Exposure Site |

Yoshimatsu Observing Station |

|---|---|---|---|---|---|

| Environment | — | acid environment |

severe acid environment |

seashore environment |

standard environment |

| Latitude | — | 31°41' N | — | — | — |

| Longitude | — | 130°49' E | — | — | — |

| Elevation | m | 322 | — | — | — |

| Avg. Temp. | ℃ | ○ | — | — | — |

| Avg. Max. Temp. | ℃ | ○ | — | — | — |

| Avg. Min. Temp. | ℃ | ○ | — | — | — |

| Avg. Ambient RH | % | ○ | — | — | — |

| Total Radiant Energy | MJ/m² | ○ | — | — | — |

| UV Radiant Energy (300-400nm) | MJ/m² | ○ | — | — | — |

| Amount of Rainfall | mm | ○ | — | — | — |

| Wind Speed | m/s | ○ | — | — | — |

| Wetting Time | h | ○ | — | — | — |

| PH Value of Rain Water | — | ○ | △※) | △※) | △※) |

| Ion Concentration in Rainwater (SO4²‾,Cl‾,NO3‾) |

mg/l | △※) | △※) | △※) | △※) |

| Amount of Ashfalls | g/m² | ○ | — | — | — |

| Amount of Sea salt aerosol | mgNaCl/(m²・d) | ○ | ○ | ○ | ○ |

※We trap and measure rainfall in containers monthly. (We measure the containers every time it rains at the Kirishima Exposure Site.)